How Companies Use ViziApps

$5 million in customer savings in the past 12 months

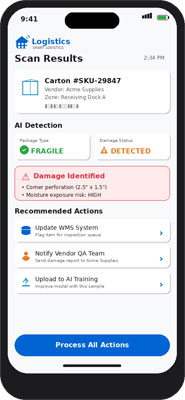

Defect Detection App

Detecting defects at the carton level is critical to supply chain velocity. This app enables distribution center and warehouse associates to leverage the power of AI with device cameras and scanners to identify incoming quality or damage issues. Associates can take action, recommend solutions, and/or add their own observations. The company’s AI/ML model analyzes the images which determine the package type (fragile, hazardous, etc.), identify damage (ripped package, perforated, etc.). The app then identifies the “next best action” workflow step, including updating the WMS system, providing feedback to the vendor quality team, and uploading Training data to the company AI/ML models.

CUSTOMER BENEFIT: Saving over $1.3M per year by providing “on the floor” immediate resolution of issues, speeding decision-making and reducing manual data entry costs and errors.

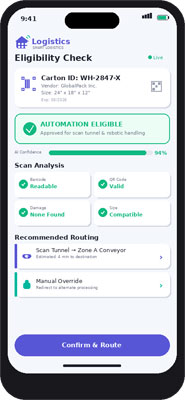

Automation Eligibility

Ensuring that incoming materials can be successfully processed by automation systems is a “must have” for effective highly automated workflows. This app enables distribution center and warehouse associates to immediately verify the eligibility of cartons for use in scan tunnels and robotic automation systems. Using the mobile device camera, it identifies the carton size and contents based on reading the multiple bar- and QR-codes, vendor IDs, and expiration dates. The company’s AI LLM model uses OCR and algorithms to recognize damaged or blurry codes, identifys text characters and identify and categorize any damage that would disqualify it for robotic handling. The app then identifies routing for the carton, with options for the Associate to intervene as the human-in-the-loop.

CUSTOMER BENEFIT: Already saving hundreds of thousands of dollars, this app increases inventory velocity, reduces labor costs, and optimizes the ROI of the automation systems while avoiding damage to expensive scan tunnel and robotic systems.

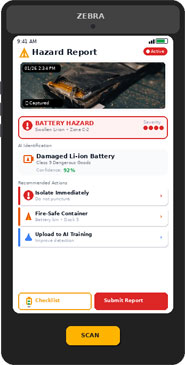

Hazardous Waste App

Quickly dealing with hazardous materials ranging from solvents to household cleaners is critical for grocery and other supply chains. This app enables distribution center and warehouse workers and quality teams to use their handheld device to quickly identify, report and remediate hazardous waste Issues. The associate can identify suspicious materials from bar code scans, photographs of containers or spills, or text entry, and report incidents from standard checklists. The app recommends actions to contain the hazardous materials and direct their safe handling and movement to designated safe storage areas for remediation. Reported hazardous waste incidents can be automatically uploaded to Train AI Models for continuous process improvement.

CUSTOMER BENEFIT: Saves the company over $2.6M per year by speeding identification of hazardous waste (timely identification is critical), ensures safe handling and disposition, and adds to knowledge base for company-wide information sharing and subsequent AI/ML Model Training..

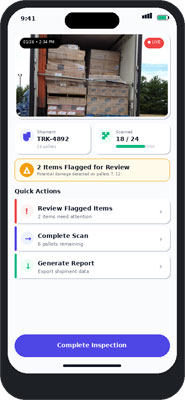

Inbound Freight Inspection

Ensuring that received shipments are undamaged and compliant with purchase order metrics is a complex task and can lead to significant delays and backups if not dealt with efficiently. This inspection app uses the associate’s mobile camera and bar code scanning to digitize the process of truckload or container incoming inspections. It consolidates the workflow from three associates using a clipboard, bar code scanner, camera, and laptop into workflow requiring a single associate. Associates can use a handheld device to scan codes, photograph damaged goods, report damage or mislabeling or contamination from a standard checklist, and automatically send the respective vendor the damaged freight credit report.

CUSTOMER BENEFIT: Reduced inspection and remediation labor costs by over $3.5M per year, significantly increased inventory velocity and optimized logistics operations, reduced paperwork and back office administrative costs, and facilitated rapid communication of issues to improve vendor quality.

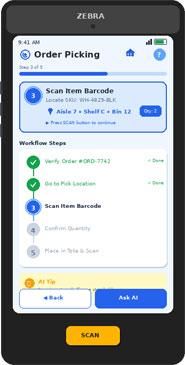

Associate SOP Workflow Agent

Ensuring that Associates are able to quickly get answers to questions and access training material is a growing challenge. This mobile AI enabled app replaces hundreds of pages of PDF Standard Operating Procedure (SOP) and work instructions manuals to provide real-time answers to distribution center and warehouse associate’s workflow instructions and SOP policy questions. Examples include guided order picking workflows, dock safety checklists, and step-by-step returns processing procedures. The company’s AI model also personalizes instructions based on the associate’s role, DC location, native language and team priorities for their current work shift.

CUSTOMER BENEFIT: The cost savings for this app scale dramatically with warehouse associate headcount. It increases inventory velocity and reduces labor costs by avoiding frequent interruptions to DC and warehouse supervisors and managers. It is especially critical for onboarding and training new logistics operations employees and seasonal workers.

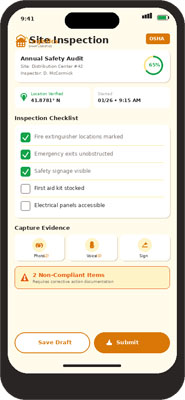

Audit and Inspection App

Companies often struggle with slow, paper-based OSHA site and other inspections that delay corrective actions and leave compliance gaps. This app enables inspectors or DC managers to access standard governance checklists, scan IDs, and report corrective actions for company-specific or industry standard (e.g. OSHA) inspections and compliance requirements. It captures GPS data to certify audit location, signatures for full accountability, photos of non-compliant issues, and voice and/or text notes. The app automatically uploads the report to company databases and further provides standardized data for agency reviews.

CUSTOMER BENEFIT: Saves over $100K per year by significantly reducing audit inspection and reporting times from days to hours, while also eliminating redundant data entry and paper-based errors, to improve audit accuracy, resulting in in such major labor cost savings and faster safety issue resolutions.